Why Does Grain Spoil?

Grain spoils in your bin because it wasn’t properly conditioned for long term storage. Adequate preparation starts with cooling your grain down after harvest and conditioning to the optimum moisture content.

Need more information? Please call 844-414-1419 or Click Here or go to 4pecks.ca.

What happens within the bin when the grain isn’t conditioned properly for future storage?

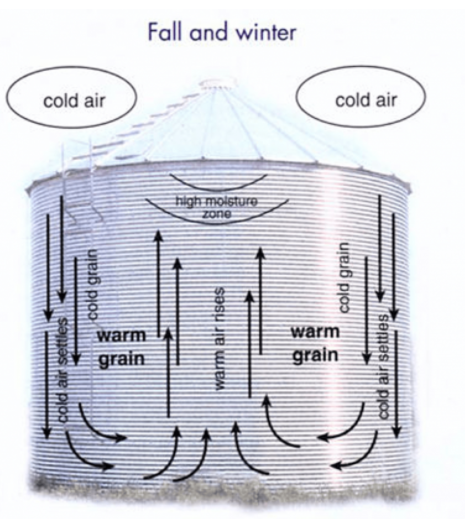

Let’s assume for this scenario, your grain has come off your field damp. With the onset of fall and early winter, colder air outside will cool the grain on the edges of your bin. Much warmer grain will be within the middle (or core) of your bin, and some of the heat may start to move upwards via convection currents. The greater the temperature difference between the grain along the side walls vs the core, the stronger the convection currents are going to be.

Cold air flows down from the surface of the grain along the side walls. The cold air flow surrounds the warmer grain held within the core. The grain from the core generates upward movement of warm air (convection) while the cold air is pulled into the core from the floor and is warmed up because it passes through the hotter grain up top before exiting the bin. This now makes the warmer air pick up moisture and condensation when it hits much colder air at the top of the bin.

The moisture at the top of the bin begins to rot the grain becoming a haven for both insects and pathogens; both are obviously not good for your stored grain.

Need more information? Please call 844-414-1419 or Click Here or go to 4pecks.ca.